PCB Assembly: The Revolution in Circuit Board Manufacturing

PCB Assembly: The Revolution in Circuit Board Manufacturing

Introduction:

In the field of electronics manufacturing, PCB Assembly (Printed Circuit Board Assembly) has emerged as a game-changer. This advanced technology offers efficient through-hole component insertion and Surface Mount Technology (SMT) assembly for circuit board manufacturing. In this article, we will delve Circuit board assembly service into the ways PCB Assembly revolutionizes the industry, its unique characteristics, advantages over traditional methods, how to select the right service provider, and conclude with its role in shaping future electronic devices.

Manufacturing Process:

PCB Assembly involves multiple steps that guarantee prec PCB Assembly ision and reliability. Firstly, designers generate schematics that dictate circuit connections on a computer-aided design software program. This data is then converted into a physical layout using Computer-Aided Manufacturing techniques. Next comes the fabrication process where printed circuits are produced following strict quality control measures to ensure opti PCB Assembly mal performance. Through-hole component insertion allows interconnection between various components through drilled holes while SMT assembly ens Through-hole component insertion ures smaller footprint by mounting components directly onto the surface of PCBs using solder paste and reflow ovens.

Characteristics:

One outstanding characteristic of PCB Assembly is its ability to accommodate complex designs with high-density components due to advancements in fabrication techniques and automated assembly processes. Additionally, it enables multi-layer stacking which enhances functionality within minimal space constraints. The use of high-quality materials ensures durability even under harsh operating conditions.

Advantages:

The u

tilization of PCB Assembly provides several advantages over conventional methods like point-to-point construction or wire wrapping. Firstly, it significantly reduces production time as automation streamlines every step from design validation to mass production stages. Secondly, it facilitates cost-efficienc PCB Assembly y due to improved yields resulting from accurate placement and soldering consistency driven by robotic pick-and-place machines with vision systems inspection capabilities.

Thirdly, reliability is enhanced as automatic test equipment can quickly identify any deficie PCB Assembly ncies before products reach end-users.

Fourthly,the compact size offered by SMT considerably lowers payload in portable devices, making them lighter and more efficient.

Usage:

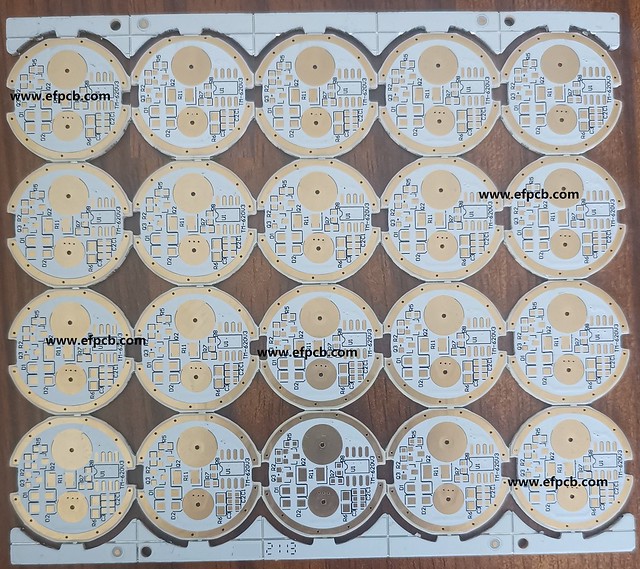

PCB Assembly is employed across various industries encompassing automotive, aerospace, consumer electronics, medical devices,and telecommunications. It caters to products like smartphones, tablets, LED lighting systems,wearable g LED PCB adgets, and many others. The technology’s versatility makes it an integral part of modern applications requiring miniaturization and improved functionality.

Selecting the Right PCB Assembly Service Provider:

When searching for a reliable PCB Assembly service provider,it is crucial to consider several factors. Firstly,the experience and expertise in handling complex designs should be evaluated. Secondly,a transparent quality control process that adheres to global standards such as ISO certifications ensures consistent production output. Thirdly,timely technical s SMT (Surface mount technology) assembly upport for design modifications or custom requirements is vital to maintain project timelines.

Additionally,customer reviews,testimonials,and collaborations with reputable brands can provide insight into the service provider’s credibility.

Conclusion:

In summary, PCB Assembly stands at the forefront of circuit board manufacturi LED PCB ng due to its numerous advantages over traditional methods.Through-hole component insertion combined with SMT assembly techniques brings unparalleled precision and efficiency.Extensive usage across diverse industries highlights its significance in driving te

chnological advancements.The proper selection of a skilled PCB Assembly service provider plays a pivotal role in ensuring successful product development.Ultimately,this revolutionary technology continues shaping our world by enabling smaller yet powerful electronic devices that enhance our everyday lives