PCB Assembly: A Comprehensive Guide

PCB Assembly: A Comprehensive Guide

Introduction:

In today’s technology-driven world, PCB Assembly plays a critical role in the manufacturing and assembly of circuit boards. From LED PCBs to surface mount technology (SMT) assembly, it PCB manufacturing and assembly is essential to understand its various aspects, features, advantages, usage methods, and tips for selecting the right PCB Assembly service.

Content:

I. Manufacturing Process:

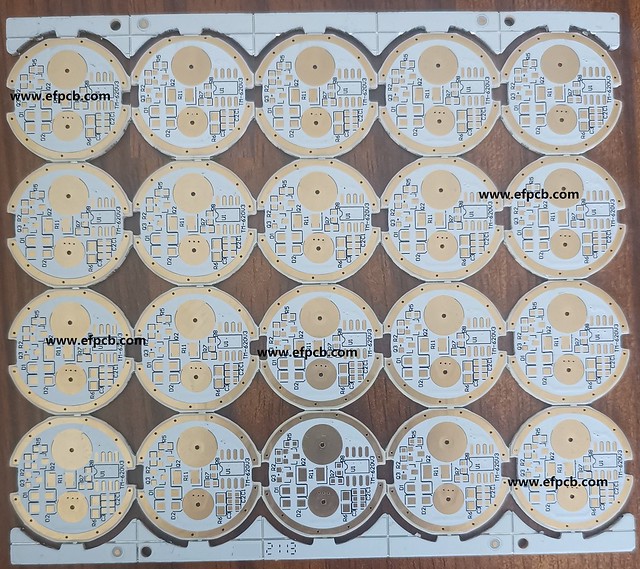

The process of PCB m Circuit board assembly service anufacturing and assembly involves several steps such as design and layout preparation, raw material procurement,

solder paste application, component placement using pick-and-place machines or manual insertion for through-hole components,

reflow soldering to join the components onto the board, visual inspection for quality control, testing for functionality assessment,

cleaning the assembled board if required.

II. Key Features of PCB Assembly:

– High Precision: PCB Assemblies are manufactured with utmost precision ensuring accurate connection between components.

– Miniaturization: With a LED PCB dvancements in SMT assembly techniques like fine-pitch placement & soldering capabilities leads

to compact boards suitable for small-sized electronic devices.

– Component Compatibility: Various types of components including SMD (Surface Mount Devices) as well as through-hole can be

integrated effectively into modern-day assemblies.

– Customizable Designs: Manufacturers offer flexibility in terms of designing layouts PCB Assembly that cater specifically to customer demands.

– Increased Reliability & Durability: Robust construction techniques ensure long-lasting performance even under varying conditions.

III. Advantages:

1. Improved Efficiency & Productivity: Automated processes reduce human errors during mounting & jointing operations leading

to increased efficiency levels on both mass production lines or low-volume projects.

2. Cost-Effective Solutions: Streamlined production cycles combined with optimized designs help minimize wastage and overall costs.

3. Quick Turnaround Time: Advanced machinery along with experienced technicians ensures shorter lead times from prototype development

till bulk production.

4. Qualit LED PCB y Assurance: Rigorous quality checks and testing procedures gua PCB component mounting rantee a higher level of reliability and functionality.

IV. Usage Methods:

PCB Assemblies find applications in various industries, including consumer electronics, automotive, telecommunications,

medical devices, aerospace, defense systems, etc. From smartphones to advanced radar systems – they are an integral part of

modern technology.

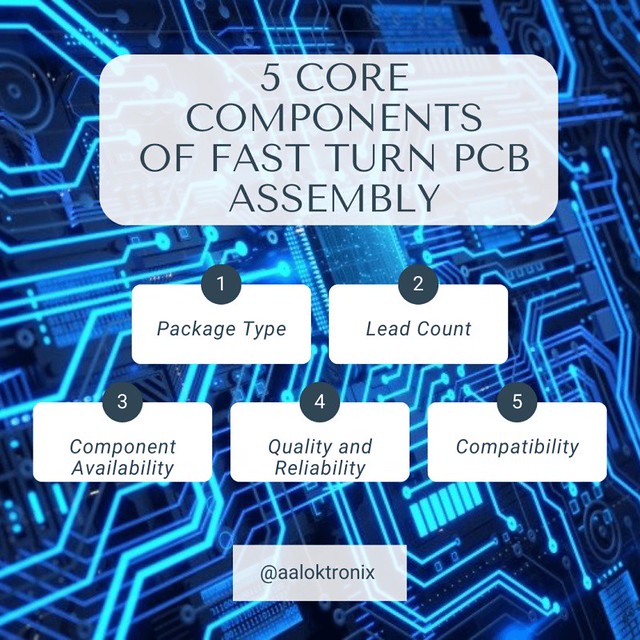

V. How to Choose the Right PCB Assembly Service:

When selecting a reliable PCB Assembly service provider for your project or product needs consider the following factors:

1. Experience & Expertise: Look for companies with extensive experience in producing assemblies similar to your requ

irements.

2. Technological Capabilities: Ensure that the manufacturer utilizes state-of-the-art machinery and techniques required for your

specific assembly needs.

3. Reputation & C PCB Assembly ustomer Reviews: Check out testimonials and online reviews from previous clients to assess their reputation within

the industry.

4. Prototyping & Testing Support: A good service provider should offer prototyping facilities along with comprehensive testing support

services as per industry standards.

5. Pricing Structure & Flexibility: Compare pricing structures offered by different manufacturers while considering any volume di PCB Assembly scounts,

special offers, or flexibility in accommodating design changes during production.

VI.Conclusion:

In summary, PCB Assembly is an essential process in manufacturing circuit boards used widely across multiple industries due to its precision,

high reliability, cost-effectiveness,and quick turnaround time.It’

s important to choose a dependable assembly service that combines expertise,

technological capabilities,and excellent customer support.Going forward,it’s expected thatthe demandforsmaller,yet more powerful electronics willcontinue driving advancementsinthePCBAssembly sector.When it comes todigitalevolution,the futureis undoubte PCB Assembly dlybrightfor this critical componentofour tech-driven world.

If you’re looking for cutting-edge PCB manufacturingandassemblyservices,don’t hesitate totakeadvantageof the latesttrends and advancementsintheindustry to createhigh-quality products that meet your business goals. Choosewiselyfor success!