Nonwoven Geotextile: A Versatile Solution for Geotechnical Applications

Nonwoven Geotextile: A Versatile Solution for Geotechnical Applications

Introduction:

Non-woven textile for geotechnical applications has gained popularity in recent years due to its excellent performance and wide range of uses. This article will discuss the manufacturing process, characteristics, advantages, Nonwoven Geotextile usage methods, tips for selecting this product, and conclude with a

summary of its benefits.

Manufacturing Process:

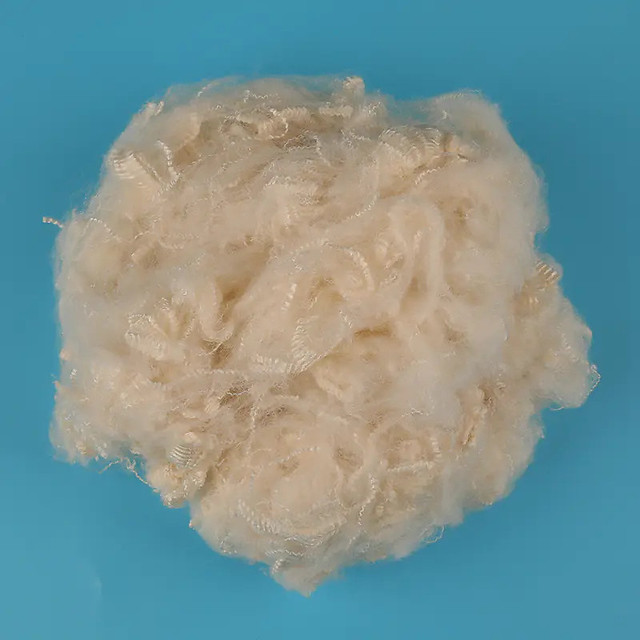

Nonwoven geotextiles are produced by entangling fibers mechanically or thermally. The fibers can be made from various materials such as polyester, polypropylene, or polyethylene. These fibers are randomly oriented and compacted together to form a porous fabric structure.

Characteristics:

The non-wove textile used for geotechnical purposes possesses unique qualities that make it suitable for diverse applications. Firstly, it exhibits high tensile strength which enables it to withstand considerable loads. Secondly, it has excellent drainage properties allo Nonwoven Geotextile wing water to pass through while retai Unwoven geotextile material ning soil particles effectively. Additionally, nonwoven geotextiles have good puncture resistance and UV stability ensuring durability under different environmental conditions.

Advantages:

One significant advantage offered by nonwoven geotextiles is their ability to separate different layers in construction projects effectively. By preventing mixing between subsoil and aggregate material layers they enhance the overall integrity of the structure’s foundation. Moreover, they provide reinforcement when place HDPE Dimple Geomembrane d beneath roads or embankments which helps in load distribution and prevents ground deformation.

Usage Methods:

Non-wove geotextiles made of nonwoven fibers find extensive application in civil engineering projects including road construction, slope stabilization measures, erosion control works as Geo-textile made of nonwoven fibers well as landfills lining systems protection.

In road construction work these textiles act as a cushioning layer between the substrate and pavement limiting damage caused by differential settlement.

For slope stabilization measures such as reinforced soil walls or steep slopes subjected to heavy rainfall these products offer effective surface drainage while providing essential containment against earth movements.

In erosion control works, nonwoven geotextiles effectively delay soil erosion by stabilizing the ground and allowing vegetation to HDPE geomembrane develop.

At Non-wove textile for geotechnical applications landfills their implementation guarantees protection against leakage through liners.

Tips for Selecting Nonwoven Geotextile:

When choosing nonwoven geotextiles, it is important to consider factors such as tensile strength, filtration properties, durability in specific environmental conditions, puncture resistance and conformance with relevant international standards. Consulting with experts or engineers experienced in geotechnical applications can be beneficial in making an informed decision regarding the selection of these products.

Conclusion:

Nonwoven geotex Nonwoven Geotextile tiles made of high-density polyethylene (HDPE) fibers are versatile materials that offer significant be Gabion nefits for various construction projects. Their manufacturing process ensures excellent performance qualities including high tensile strength and drainage capacity. By acting as a separation layer, they enhance the stability of structures and prevent soil particle migration. These textiles find wide usage in road construction, slope stabilization measures, erosion control works

and landfill lining systems protection proving their worthiness in diverse applications. When selecting nonwoven geotextiles, proper consideration of their characteristics based on project requirements guarantees optimal results leading to successful outcomes across different engineering endeavours.