PCB Assembly: Manufacturing, Characteristics, and Benefits

PCB Assembly: Manufacturing, Characteristics, and Benefits

Introduction

In the field of electronics manufacturing, printed circuit board (PCB) assembly plays a crucial role in creating functional and reliable electronic devices. HDI PCB By combining various components onto a single board, PCB assembly enables the creation of intricate electronic systems. In this article, we will explore the different aspects of PCB assembly, includi Through-hole component insertion ng its manufacturing process, characteristics, advantages, usage methods, tips for selecting a manufacturer, and conclude with key takeaways.

Manufacturing Process

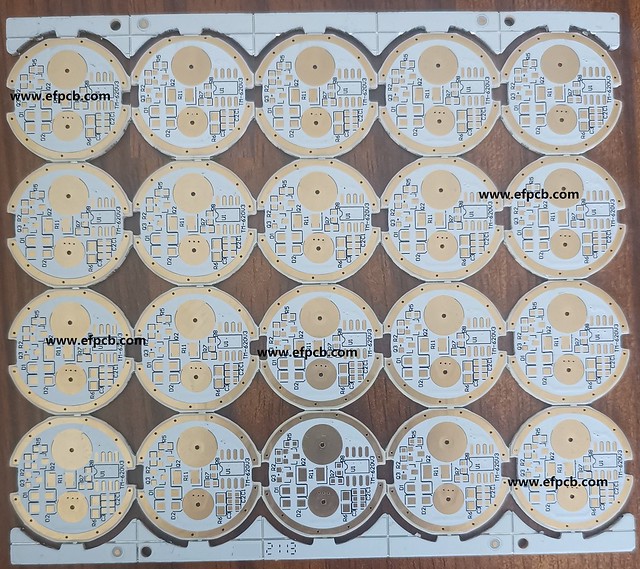

There are two primary methods used in PCB assembly: SMT (Surface Mount Technology) assembly and through-hole component insertion. SMT assembly involves soldering surface-mount components dire PCB Assembly ctly onto designated areas on the PCB using automated machinery. Through-hole component insertion requires parts to be inserted into pre-drilled holes on the board before being soldered manually or automatica

lly.

Characteristics

PCB population is an essential part of board manufacturing and includes placing all necessary components onto the bare circuit boards. This step is followed by precise soldering techniques that ensure secure connections between the components and the conductive traces on the board. Apart from ensuring proper electrical connectivity within an electronic system,

PCBA also provides mechanical support to delicate components.

Advant

ages

The use of PCB assemblies offers several notable advantages over other wiring methods:

1. Compact Design: Assemblies allow for complex circuitry designs to be condensed into smaller spaces.

2. Consistency & PCB Assembly Reliability: Automated processes guarantee uniformity in component placement throughout production batches.

3. Vibration Resistance: Securely attached components minimize possible disconnections caused by vibrations or movement during device operation.

4. Ease of Diagnosis & Repa PCB population and soldering ir: Modular design facilitates troubleshooting and efficient replacement if any faulty component is identified.

Usage Methods

PCBs find widespread application across multiple industries such as auto PCB manufacturer motive technology,

telecommunications equipment development

medical device manufacturing,

and consumer electronics production . They are employed primarily due to their ability to streamline product assembly, improve product reliability, and reduce manufacturing costs.

How to Select a PCB Assembly Manufacturer

Choosing the right PCB assembly manufacturer is crucial for ensuring quality productio SMT (Surface mount technology) assembly n and timely deliveries. Here are a few key factors to consider during this selection process:

1. Expertise & Experience: Look for manufacturers with proven experience in producing similar products within your industry.

2. Quality Control Measures: Inquire about their quality control processes to ensure that they adhere to industry standards.

3. Customization Options: Assess if the manufacturer can cater to your specific design or volume requirem PCB Assembly ents.

4. Pricing & Delivery Timeframes: Obtain quotes from multiple manufacturers and compare pricing structure along with estimated delivery times.

Conclusion

PCB A Multilayer PCB ssembly plays an integral role in modern electronics manufacturing due to its numerous advantages over traditional wiring methods. Whether it’s SMT assembly or through-hole component insertion, choosing a reputable manufacturer is critical for deli

vering high-quality end products. By considering expert knowledge, customization options, pricing, and delivery timeframes when selecting a manufacturer,

you can ensure efficient production cycles while maintaining product reliability.