PCB Assembly: An Introduction to Manufacturing and Integration

PCB Assembly: An Introduction to Manufacturing and Integration

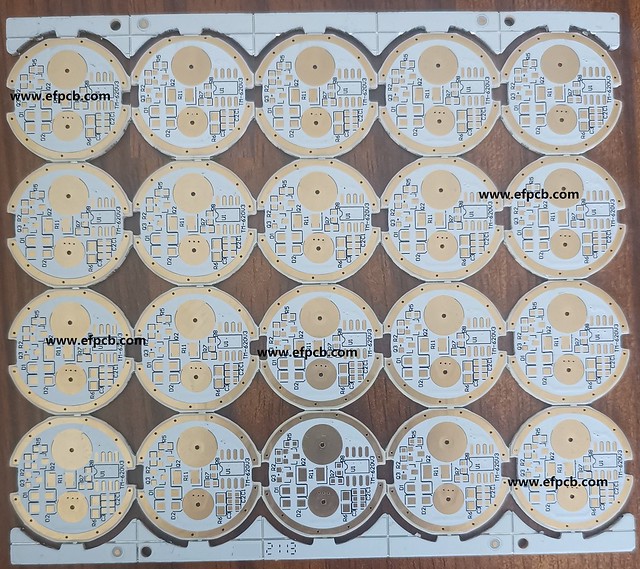

In today’s rapidly advancing technology landscape, electronic devices have become an integral part of our daily lives. From smartphones to smart home appl Board-level integration iances, these devices rely on the proper functioning of Printed Circuit Board (PCB) assemblies. PCB Assembly is a crucial process in electronics manufacturing that involves mounting various components onto a PCB for seamless integration. This article will discuss the different aspects of PCB Assembly, includin PCB Assembly g its manufacturing methods, characteristics, advantages, usage guidelines, tips for selecting a reliable manufacturer, and conclude with key takeaways.

Manufacturing Methods:

PCB Assembly can involve two primary methods – Surface Mount Te PCB component mounting chnology (SMT) assembly and Through-hole component insertion. SMT assembly is widely used due to its high-spe

ed production capabilities and ability to mount components directly onto the surface of the PCB using automated machinery. On the other hand, Through-hole component insertion involves manually inserting leads through drilled holes on the board before soldering them in place.

Characteristics:

One notable characteristic of PCB Assemblies is their compactness and complexity. With advancements in miniaturization techniques, manufacturers ca PCB Assembly manufacturer n pack more functionalities into smaller boards while ensuring reliability and durability.

Advantages:

The advantages of utilizing PCB Assemblies are manifold. Firstly, they improve circuit reliability as soldered connections are less prone to damage caused by vibrations or mechanica PCB Assembly manufacturer l stress compared to point-to-point wiring. Additionally, these assemblies s PCB Assembly treamline production processes by eliminating complex wire routing tasks associated with traditional circuit construction methods.

Usage Guidelines:

When working with PCB Assemblies during device development or repairs/modifications/upgrades/replacements:

1. Ensure compatibility between hardware components and assembly types.

2. Consider power requirements carefully.

3. Follow recommended operation temperature ranges.

4.Apply Electrostatic Discharge (ESD) protection techniques during handling/maintenance.

5.Disp

ose/recycle old or faulty assemblies properly following local regulations.

Tips for Selecting a Reliable Manufacturer:

As an informed buyer, it is essential to consider a few factors when selecting a PCB Assembly manufacturer:

1. Evaluate their expertise and experience PCB manufacturing and assembly in the industry.

2. Check for certifications such as ISO 9001 or IPC-A-610 standards compliance.

3. Assess their quality control processes, including inspection and testing procedures.

4. Inquire about the ava PCB Assembly ilability of design support services for customization needs.

5. Request references or customer testimonials to gauge satisfaction levels.

In conclusion, PCB Assembly plays a crucial role in ele

ctronics manufacturing and integration processes. By understanding its different manufacturing methods, characteristics, advantages, usage guidelines, and tips for selecting reputable manufacturers; businesses and individuals can ensure seamless device functionality with reliable PCB Assemblies that meet their specific requirements.

Remember to choose trusted PCB Assembly manufacturers to ensu PCB Assembly manufacturer re high-quality products through diligent research and evaluation process!