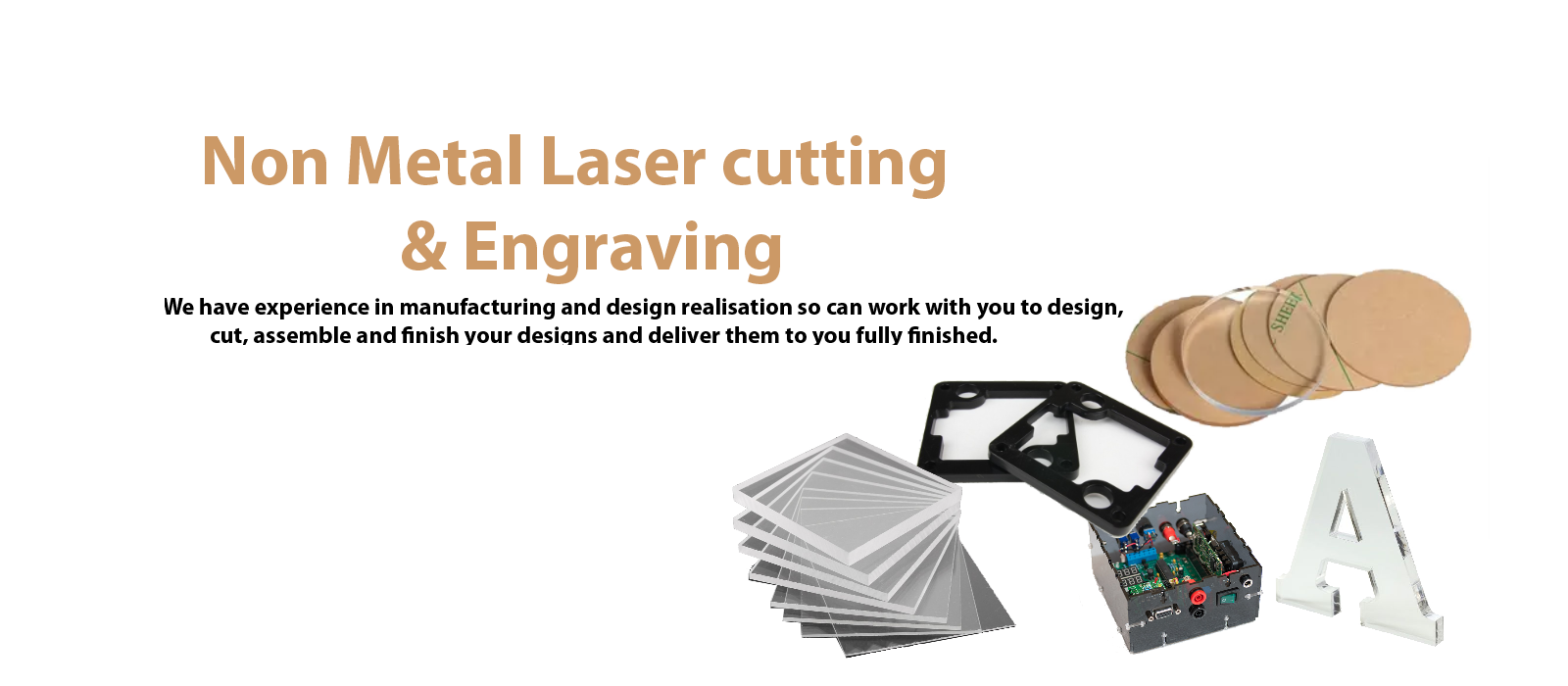

Non-Metal Laser Cutting and Engraving

The most popular upgrade for cutting and engraving metal objects is https://www.angelo-home.com/. These machines are known to improve work efficiency and reduce costs, while increasing productivity. In addition, they are used to cut various materials and thicknesses. These machines have obvious advantages over other types of cutting machines. Manufacturers of Suzhou laser engraving machines employ imported high-precision screw rods and linear guides, which enable the machines to move smoothly over the workpiece.

The SFX 180W Reci W8 CO2 Laser Engraver Cutter Machine features an air-assisted engraving feature. This machine supports AutoCAD and CorelDraw, and supports both bmp and dxf files. Additionally, the engraver has a built-in air pump and exhaust fan. This machine weighs 946 pounds. This machine is capable of cutting through metal, plastic, and plexiglass.

Industrial-grade industrial laser engraver offers high-performance industrial-level performance and compatibility with the most popular software solutions. It can be used for cutting, engraving, and engraving a variety of materials, including stainless steel, aluminum, copper, and aluminum. Moreover, it comes with free technical support and video training. Besides, it can also be used for laser etching, which is a method of changing the color and depth of a metal surface. After the process, a raised area is left behind. Metals commonly used for laser etching include copper, stainless steel, and aluminum.

The MCWLaser laser engraver has 20 watts of power and a 110×110-millimeter work area. It utilizes the Raycus laser technology and can engrave a variety of hard and soft materials. The MCWLaser laser engraver can handle various metals and non-metal materials. It is the perfect desktop engraving machine.

The most important difference between non-metal and metal cutting is the beam focus height. When cutting metal, the laser beam must pierce the material before moving on to the next cut. During metal cutting, this process is crucial because the beam must penetrate through a dense material before melting it away. Unlike non-metal materials, however, this step is not required for non-metal cutting. https://www.angelo-home.com/product/marble-color-uv-mdf-high-gloss-board-price/ tends to require finer focus and frequency adjustments.

The Snapmaker 2.0 Modular 3-in-1 is an excellent choice for professional metal work. This machine features auto-leveling, filament runout recovery, and power loss recovery. It can be used to engrave metal, plastic, and non-transparent acrylic. Its versatility makes it a valuable asset to the arts and crafts industry. Besides engraving, this machine can also perform CNC carving, which enables a variety of other metal cutting and engraving projects.

The new Ortur Laser Master 2 Pro has upgraded features and an ergonomic touchscreen for easy operation. With an expected lifetime of 8,000 hours, this machine can be used to mark metal items and even small details. And it offers unlimited support. You can also buy a second machine if you need to use it for engraving metal objects. In either case, it will be worth the money to invest in a non-metal laser marking machine.